Create, Solve, Innovate: Collaboratively Developed, ESU 11 Lab Sets Students Up For the Future

Create, Solve, Innovate: Collaboratively Developed, ESU 11 Lab Sets Students Up For the Future

Tyler Dahlgren

Welcome to Stephanie Dannehl’s library, where, contrary to the cliche, you’re not supposed to be able to hear a pin drop.

Inside Bertrand Community School on a cold Tuesday in January, the space is alive and humming with enthusiasm. ESU 11’s CSI Lab, a mobile makerspace containing 10 high-tech stations, is here for the next two weeks, a perfect fit for a place that’s sending students forward, into the future, by flipping all of the library stereotypes you can think of, well, backwards.

“This is what I’ve always wanted the library to be, not some quiet, shushed place,” said Dannehl, Bertrand’s Library/Technology Integration Specialist. “It’s a place where kids can explore and find different opportunities to learn whatever interests them. The CSI Lab is perfect for that.”

Create. Solve. Innovate. That was the goal when ESU 11 Administrator Dr. Greg Barnes first collaborated on the matter with Royal Engineered Composites President Dave Arnold and the Phelps County Development Corporation, who contributed $15,000 right off the bat to make the lab a reality.

The program was developed out of collaboration, and operates to provide opportunities for students in southcentral Nebraska, where technical careers in the skills and trades exist in abundance. The ability to problem-solve, create and innovate is moving back to the forefront of education again. For free-thinkers, there's plenty of doors to be opened.

“This is an opportunity for the students to start thinking about what types of work they might enjoy, whether it’s graphic design, pneumatics or one of the other labs they are able to work in,” said Dr. Barnes. “And, bottom line, we’re trying to encourage them to start thinking about not just their career, but a career in southcentral Nebraska.”

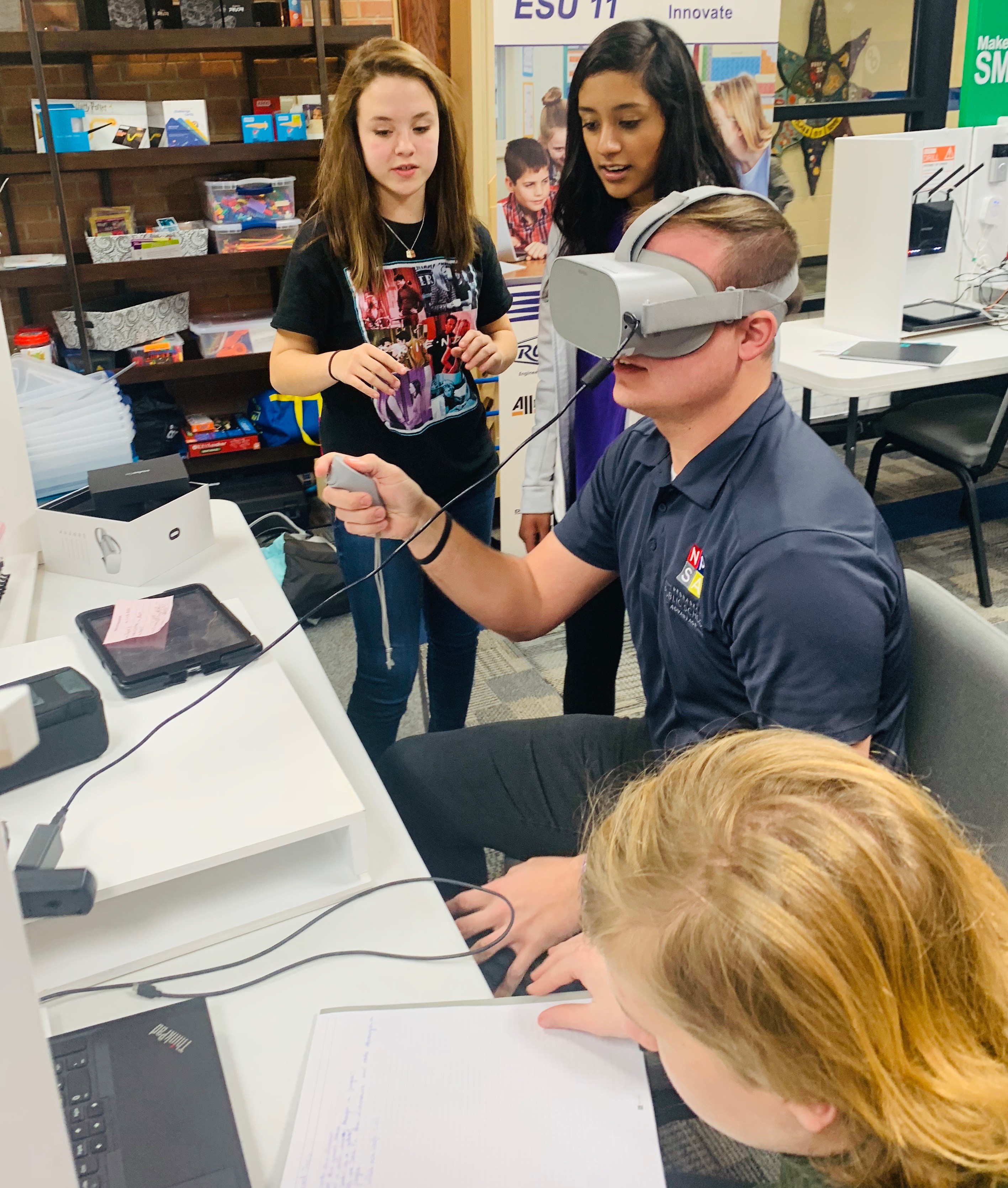

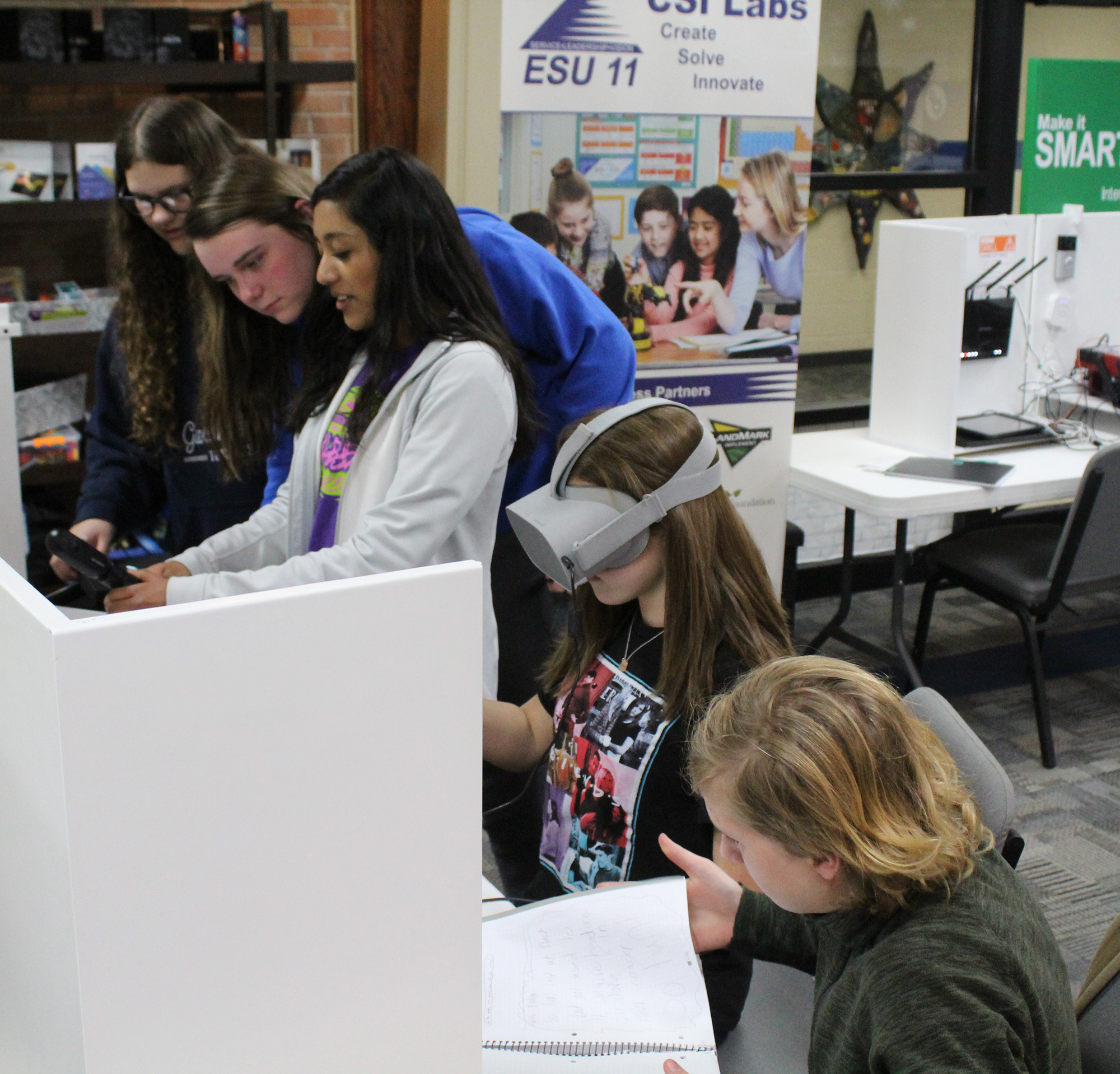

Modeled after Nebraska Public Power District’s mobile makerspace, the CSI Lab launched this past fall and rotates between ESU 11’s 13 school districts, spending two weeks at each stop. The 10 stations all fall under four themes: Make It New, Make It You, Make It Do and Make an Impact. With access to new technology like virtual reality, robotics and a 3D printer, students are given an orientation and then set free to discover.

“When you walk around and watch the kids, they are totally engaged,” said Dannehl. “They aren’t watching the clock or counting down the minutes until class ends. You can see and feel the excitement. Their lightbulbs are on.”

The CSI Lab was modeled for seventh and eighth-graders, but is also made available to older students as well. Students, Dannehl said, need to be prepared for the future, for jobs which don’t even exist yet. Two weeks in the lab offers them the opportunity to grow like skills, too.

“We have to get these kids to be thinkers, creators, designers and problem solvers,” Dannehl explained. “If they can do those kinds of things, they can do about anything.”

For the businesses involved, like Royal Engineered Composites, there’s no safer investment to make than in area youth.

“We need a workforce,” said Tim O’Dey, Royal’s Engineering Manager. “We need a workforce now and we need a workforce going into the future. So we’re doing what we can to develop interest in technical-type trades. What we do is technical work, and we want to give kids an opportunity to put their hands on things, to be able to see how things work, and to develop some interest in those career opportunities.”

Workforce is an issue across Nebraska, not just in Phelps County, a large reason community corporations and schools are linking up to open doors for area students. Fred Diedrichsen, Director of the Phelps County Development Corporation Board, enjoyed watching students utilize the lab on Tuesday.

“We want to create jobs and we want to keep people in the community,” said Diedrichsen. “We’ve decided that if we can train kids and keep them at home, in careers that allow them to have good livelihood and to prosper, we’re going to solve some of our workforce problems.”

O’Dey was on hand Tuesday to see the lab in action. The employees his company has had the best luck in recruiting and retaining in previous years are the ones accustomed to the rural Nebraska lifestyle.

“On the flip side of the coin, it’s really nice when, as a community, you know that you’re going to have people that are going to stay in your community, make a decent wage, put money back into the economy and keep businesses open on Main Street,” O’Dey said. “We hope this program continues to grow. There’s a need for it.”

Monica Boyken is the CSI Lab’s Coordinator, and brings a business background to the role. The lab connects both entities, the school and businesses, economically and rounds out a rather large cycle, which begins when a company puts forth money to provide new learning opportunities for students and ends in a return on that investment when those students bring their acquired skills into a possible employment down the road.

“It is really fun to be able to incorporate the idea that these are career-specific skills that they’re going to gain through this,” said Boyken. “Standing in front of the students on Orientation Day, and seeing those eyes flare open and hearing the ‘Ooohs and Aaahs’, it’s just such an exciting feeling.”

The students’ time in the CSI Lab is fast and furious. The bell ringing usually comes as a surprise.

“It’s more entertaining actually learning hands-on instead of just watching videos or taking notes off a Powerpoint,” said junior Landon Andersen, whose future beyond Bertrand High School just might include engineering. “We are actually experimenting and making our own creations. It’s cool because you can see what goes on in the boards that you find in your phones and remote controllers and video games.”

Boyken tells students at each school district that there’s three skills in particular she hopes they gain over the course of their time with the lab. The first is simply the ability to “figure it out”. Then, there’s patience. Unlike our cell phones and laptops, there isn’t a piece of equipment in the CSI Lab that doesn’t take some time to fire up.

And, finally, there’s failure, which, in this setting, is stripped of its negative connotations. Inside these walls, a failure is just another step towards something special. Towards a solution.

“None of us really wants to go out there and fail,” Boyken said. “We’re all striving for As and Bs, but this is a place where failure isn’t a bad thing.”

Employers are searching for candidates with the ability to think outside of the box, explained Bertrand Industrial Technology teacher Bill Ford, who has been in the district for 25 years. While working in the CSI Lab, the process is just as valuable to his students as the skills gained by working with the new tools.

“They’re not given any answers and they’re not given any demonstrations,” said Ford. “The whole idea is to go out and try to seek the information. They’re not just learning how to use the equipment, but they’re learning how to apply the equipment.”

For Ford, learning alongside his students has been an absolute blast. For a change, he doesn’t hold all of the answers. He encourages the kids to go exploring and is tickled when they come back from their journey with an answer.

“And I expect them to teach me as soon as they find out,” he laughed. “What’s really cool is when they get to teach the teacher. They puff their chests out a little bit. It’s pretty neat to see.”

At the onset, Dr. Barnes and community business partners set a three-year goal for the CSI Lab, long enough to give the equipment a useful life. After the third year, the lab will be evaluated and could potentially extend into a fourth. Ideally, the lab, which operates off donations from businesses and industries, would inspire districts to one day look at incorporating similar STEAM curriculum.

“The whole goal of the group was to spark enough interest in the schools so that they would then carry the torch forward in their own buildings,” Barnes said. “It’s a great opportunity for business and industry and education to work together on something.”

Nobody knows exactly what the future holds.

“These students can do anything,” said Dannehl. “Maybe they’ll even use some of these skills to create the job that doesn’t exist right now.”

Dreaming is what makes this venture so much fun.